Reduce Costs With Hybrid Technology

This is part of a continuing series of “how-to” articles to help you maximize performance and productivity with Toro® products.

Hybrid vehicles are touted for their dramatic fuel savings. But in terms of grounds maintenance equipment, Toro hybrid mowers, such as the Greensmaster® TriFlex™ Hybrid, Greensmaster® eTriFlex™ Hybrid and Reelmaster® 5010-H, extend savings and lower fuel costs.

This article will cover how to use hybrid mowers to lower expenses and increase cutting efficiency. We’ll also cover how to troubleshoot hybrid machines, which is a little different from traditional equipment.

Understanding Hybrid Technology

When two different power sources work together to power equipment, that’s hybrid technology. In Toro’s Reelmaster 5010-H, the internal combustion engine is supplemented with power from a 48vdc battery system and generator. The energy stored in the battery system is released when needed, working in concert with the diesel engine and electric generator to provide extra power for the traction system as well as drive the electric reels. Reels driven by electric motors run at a constant speed regardless of engine rpm.

Greensmaster TriFlex and eTriFlex hybrid machines use an internal combustion engine that drives a generator and a 48vdc battery system. The energy stored in the battery system is released when engaging the reels. This process assists in getting the reels up to speed quickly and absorbs energy when the reels are spinning down after disengagement.

Both hybrid systems are highly fuel efficient.

Beyond Fuel Savings

While the system of the internal combustion engine driving hydraulic gear pumps and motors to turn the cutting unit reels has been in use for many years, it is not the most efficient. Only around half of the energy from the engine (input energy) reaches the reels (output energy) to cut grass. As hydraulic components start to wear internally, the efficiency is even lower because of the internal leakage of pumps and motors. This results in less power and slower reel speeds. The technology used in Toro hybrid mowers changes that because the battery collects and stores excess energy, such as the kinetic energy generated by braking, and reuses that battery energy so waste is greatly reduced. The result is a significant reduction in fuel consumption as well as time saved by making fewer trips to refuel.

And the savings don’t stop there. Because the hybrid technology provides power through the battery, a smaller engine can be used without a sacrifice in performance. The smaller engine conserves more fuel, plus it comes in under Tier 4 mandates.

The other great source of savings for grounds applications is a significant reduction in hydraulic maintenance expenses and the potential for reducing turf-damaging hydraulic leaks.

Reduced Hydraulics

For golf courses, sport fields and other grounds maintenance areas, hydraulic leaks can make a quick mess of pristine turf. Fortunately, the efficient design of Toro hybrid mowers replaces reel-drive circuit functions with electronics, practically eliminating leak potential from the reel circuit.

In addition to limiting turf damage and maintenance, the reduced hydraulics also save significant service costs. Based on a recommended service interval of 1,000 hours per year, the annual savings in hydraulic oil, replacement hoses and filters, and labor costs can top $1,100. That can really add up year after year.

Outstanding ROI

The hybrid system also allows for design features such as flocked seals that reduce drag on the cutting units so less power is needed to turn them. Because they’re driven by electronics rather than hydraulics, the reels also operate at a constant speed, so you get consistent cut quality minute by minute, hour after hour.

The bottom line is that you’ll have a better bottom line with Toro hybrid mowers like the Toro Reelmaster 5010-H. A mower that uses hydraulic systems requires more engine horsepower to operate, plus it has higher fuel and maintenance costs and time requirements. You’ll save money with Toro hybrid equipment while also helping to reduce fuel consumption. Toro all-electric Greensmaster eTriFlex™ mowers are also available.

Troubleshooting Hybrid Equipment

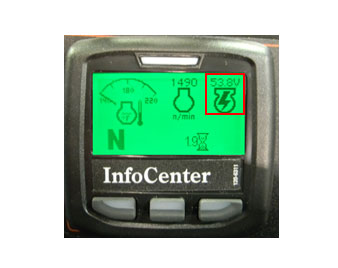

As with traditional equipment, Toro hybrid mowers are equipped with an InfoCenter that provides operating and troubleshooting information.

The top right corner, for instance, displays the generator status and hybrid system voltage. When the generator is on, the lightning bolt icon will be a solid black. The system voltage is right above it for easy reference. At full engine throttle, this voltage should be approximately 54.0vdc.

The InfoCenter on the Reelmaster 5010-H also includes a temperature gauge, which is particularly valuable when mowing in dry conditions, scalping or verti-cutting.

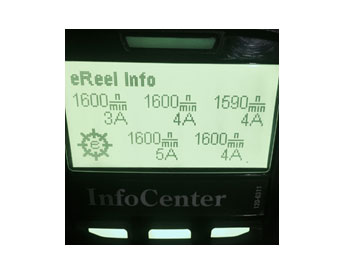

Use the eReel Info screen to view the motor speed and the current being drawn. If the motors aren’t running at the same speed or one is drawing excessive power, that could indicate a reel bearing issue or the need for a bedknife adjustment.

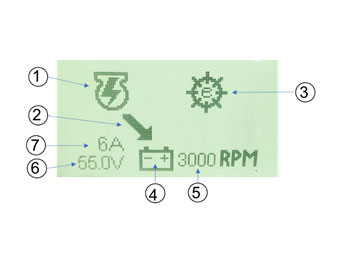

View the operator screen to see the power distribution in the RM5010H hybrid system. The dark arrow indicates the power path. In the example here, power from the generator is going to charge the on-board battery pack.

- Generator Icon

- Black Arrows Show Current Flow

- eReel Motor

- 48vdc Battery Pack

- Engine RPM

- Hybrid Bus Voltage

- System Current

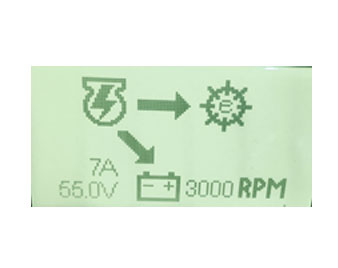

When the reels are engaged, you can see power flow to drive the eReel motors as well as charge the battery pack.

When mowing up a steep incline, the battery provides power to the eReels and to generator, which drives it as a motor to assist the diesel engine to give the machine the extra power it needs.

To learn more about Toro hybrid mowers, contact your local Toro distributor.

More How-To Help

The how-to series is designed to help you get the most from your Toro equipment. If you missed any of the previous articles, just click on the titles below. You can also check out our Video Hub for more how-to instructions and advice.

Extending the Life of Your Sprayer

Maintaining the Ideal Quality of Cut

Extending Equipment Life With A Fuel Stabilizer